Engraving a plaque or a sign is an efficient way to add a sophisticated twist to your signs. We provide two different engraving services – laser engraving and rotary engraving. So, depending on your clients’ needs, we can offer you the opportunity to deliver their requests. Rotary engraving machines have specific functions that are unique to the machines such as an electronic surface detection system. This feature allows the machine to automatically detect the surface of the material that it is going to engrave. Once it has been detected, the Z-axis adjusts to the material to ensure consistent and even depths of engraving. This method is most useful when engraving uneven surfaces, but is restricted to rigid materials such as Traffolyte, Acrylic, Brass and Stainless Steel.

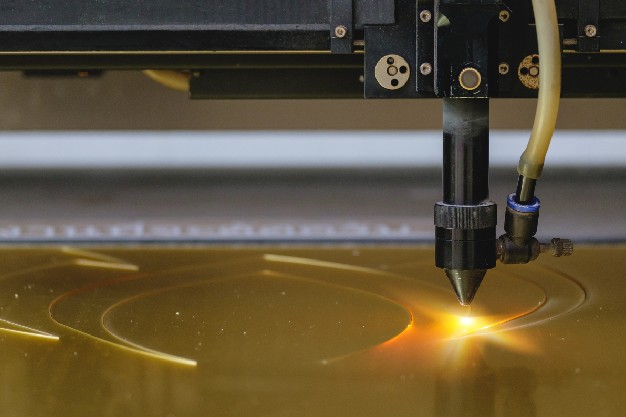

Laser engraving has come on leaps and bounds in the last few years. It is now extremely user-friendly, faster and cheaper than rotary engraving. With laser engraving, it is possible to reduce the production time by a significant margin. Your imagination is the limit with laser engraving – it allows for a multitude of designs to be programmed for engraving. It also provides engraving for more versatile materials, not just rigid materials like the rotary engraving does, but materials such as fabrics, leather, latex and rubber, among many more.

Laser Engraving materials:

- Paper, card and print media

- Fabric

- Leather

- Acrylic, nylon and other non-PVC plastics

- Plastic laminates

- Latex and rubber

- Plywood and MDF

- Wood and wood veneers

- Glass, granite, slate and marble

- Anodised and coated metalsv

- Uncoated metals*

Rotary Engraving materials:

- Traffolyte

- Acrylic

- Anodised Aluminium

- Durablack

- Engraving Brass

- Stainless Steel