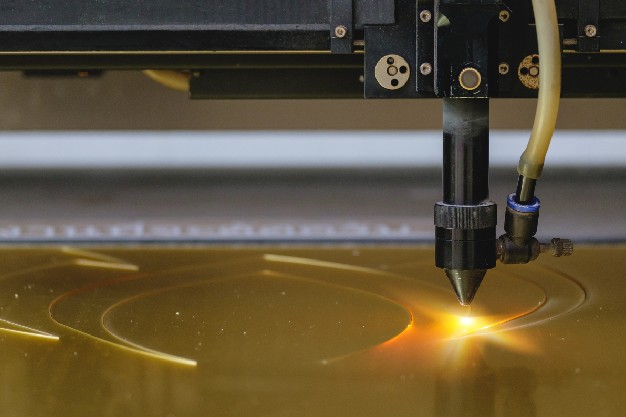

For laser cutting, we own an LS6090 HPC Laser. Its 900mm x 600mm bed size offers efficiency and productivity but also remains compact and professional. Its water-cooled CO2 glass laser tube allows it to be able to work with all sorts of materials such as paper, card, fabrics, leather, plastics, rubber and wood, meaning that it is a very varied method of signage production.

Usually used for smaller projects, the laser can be programmed to cut out the design that your customer has in mind. As it is a single beam, there is no issue with the rest of the tool getting in the way of sharp angles and crisp-cut and intricate designs

Thanks to the manufacturing techniques that are involved in laser cutting, there are lots of pros to this technology. The most obvious is precision – as a typical laser beam is on average 0.2mm in diameter, laser cutting allows intricate precision. Additionally, the materials used do not warp under the heat as the laser is extremely fine and non-invasive. Laser cutting is perfect for detailed and intricate designs as the laser can get into very small spaces and can cut sharp angles with no restriction. Another pro to laser cutting is the vast array of file types it can work from, meaning that the process of bringing a design to life isn’t impaired by fiddling around with document types.

There is a range of materials to choose from:

- Paper, card and print media

- Fabric

- Leather

- Acrylic, nylon and other non-PVC plastics

- Plastic laminates

- Latex and rubber

- Plywood and MDF

- Wood and wood veneers